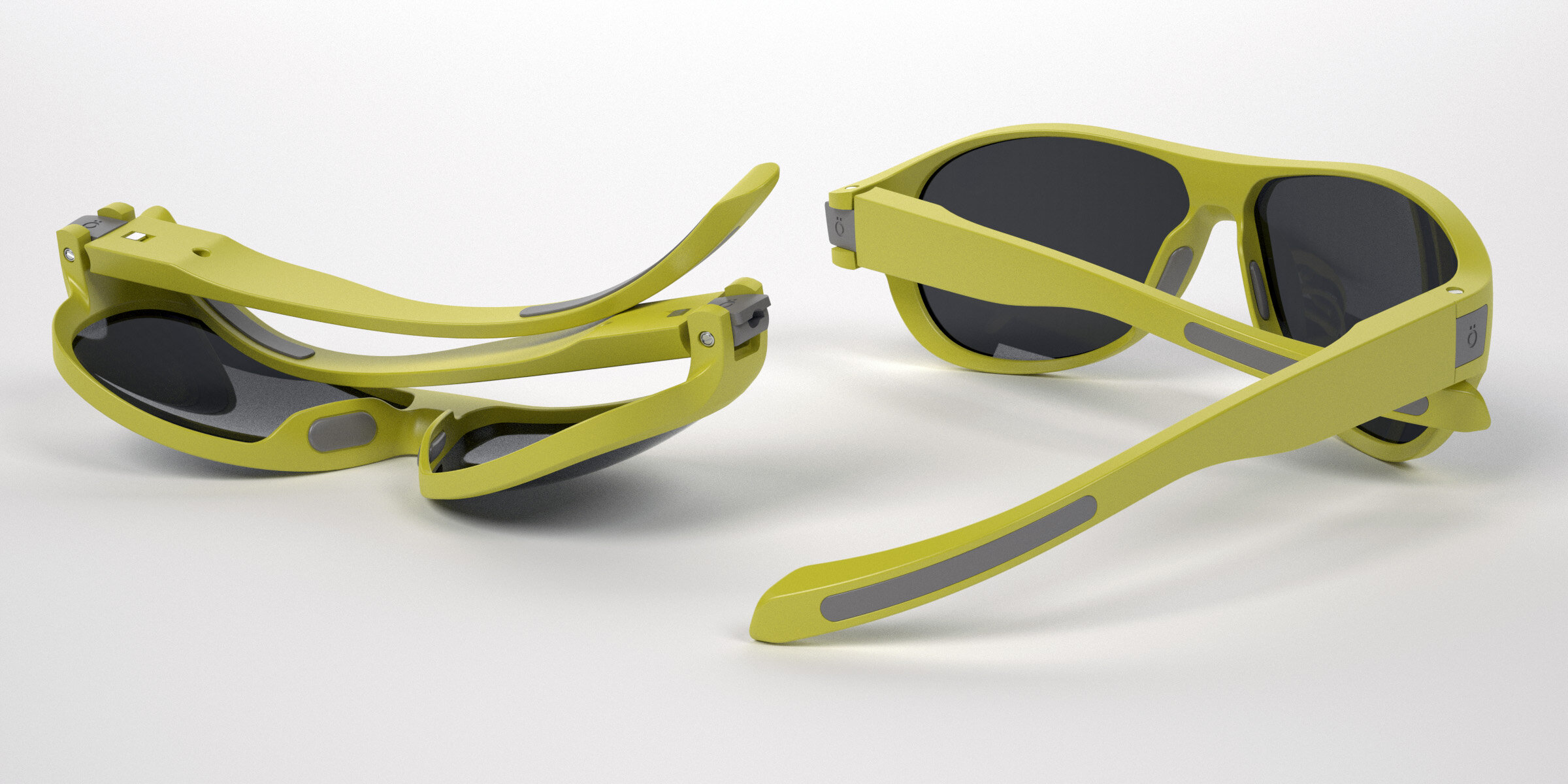

Götti Eyewear

2014-2015

From 2014 to 2015 David worked at Götti in R&D, building up the know-how in-house to design fully parametric 3D printed eyewear, which can be adjusted individually, for a perfect fit for each customer.

Research and Development of eyewear collections manufactured on selective laser sintering machines (3D printing) from concept to readiness for on-demand production.

Parametric free-form surfacing on all models (class A) in Siemens NX, with scalable areas like the saddle bridge, glass size or temple length for a perfect individual fit.

Ergonomic studies.

Dyeing and coating research in collaboration with EMPA.

Development and engineering of hinges suitable for SLS parts.

Training of a design engineer in class-A surfacing to take over the established modeling methodology once the research was done.