Victorinox

2016-2017

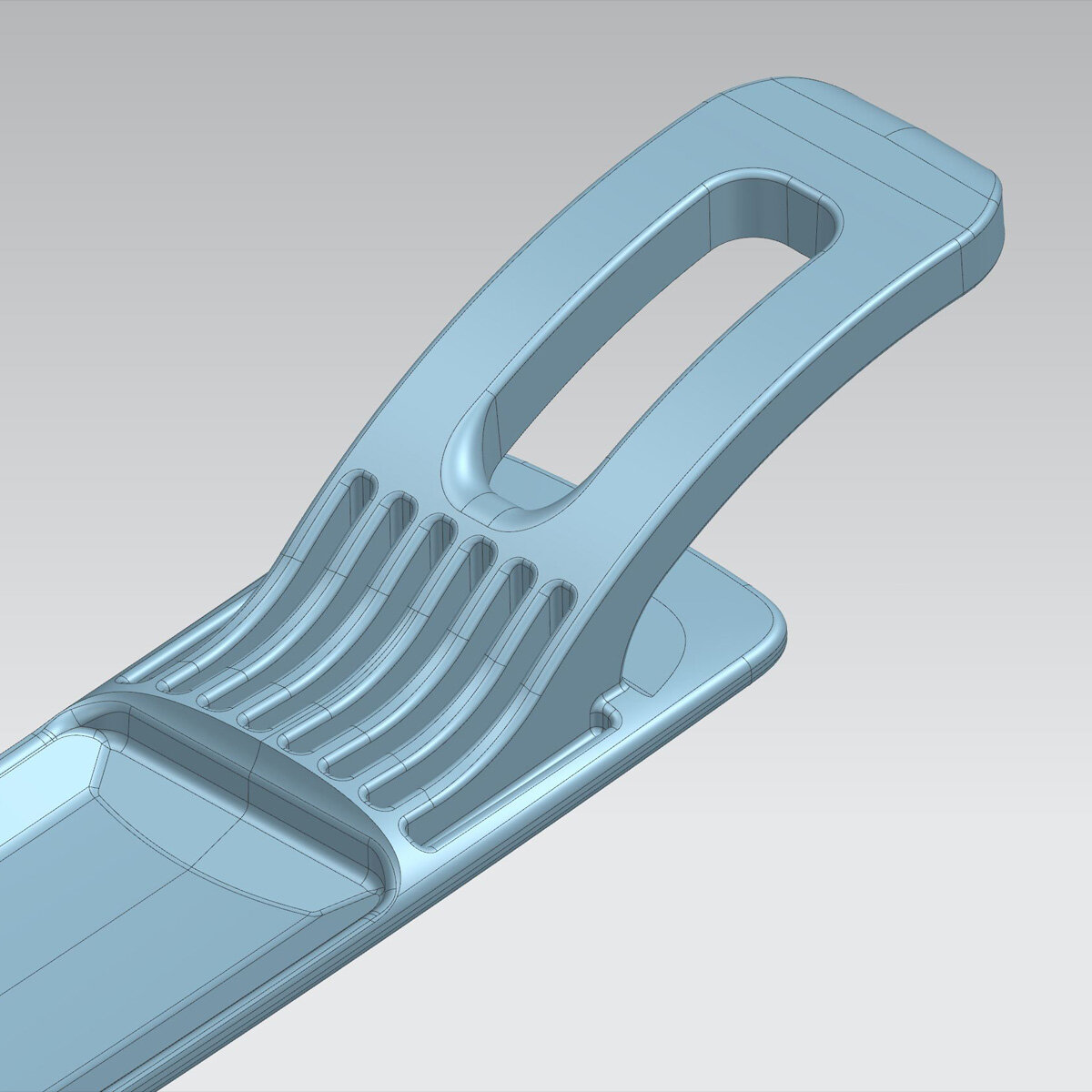

David worked as a lead engineer at Victorinox Travel Gear from 2017 to 2018. Leading a small team of engineers and CAD designers he built up the engineering know-how in-house for lightweight, complex injection molded parts, that had to withstand extreme loads, a task that was formerly sub-contracted to suppliers in Southeast Asia.

Research & Development of molds, luggage components and lightweight structures for the travel gear industry, from concept to prototype to large scale production.

Design & engineering of highly complex injection molded parts as class-A surfaces, ready to be used for tooling, including draft angle analysis, thickness analysis, and basic mold flow analysis.

Design & engineering of fully parametric, class-A surface, compression & vacuum forming aluminum molds.

Validation of parts and assemblies via FEA.

Travel to manufacturing partners and setting up best practices, coordination and tooling in China, Vietnam, Thailand and Japan.

Training of new CAD designers in Siemens NX and parametric class-A surfacing. Close collaboration with designers and translating their ideas into mass manufacturable components and assemblies.